Radians Knowledge Base

Hand Protection Solutions

Choosing the right glove is imperative to protecting your hand. The three main components of a cut protection glove are the glove's cut level, shell material, and palm coating.

Radians line of cut, coated, and leather gloves utilize the latest technologies to offer you the best glove selection on the market. Read below to learn more about the components of a good glove and what solutions Radians has to offer.

Protecting your hands.

Your hand has 29 bones, 29 joints, 3 major nerves, and 30 named arteries. Protecting this complex part of your body requires specially designed and engineered PPE. Cut protection gloves offer varying levels of protection against cuts while on the jobsite.

Failure to use the proper hand protection can lead to serious injuries and serious financial consequences. Injuries to the hand resulting from the lack of wearing gloves accounts for over 1 million emergency room visits. Hand injuries cost employers hundreds of millions of dollars a year. OSHA violations for non-compliance of hand protection cost an average of $6,000 per citation.

Standards and Testing

Standardized testing of gloves ensures that the proper glove can be selected based on the hazards present. Testing includes ratings for abrasion, cut, tear, and puncture.

The two glove standards are the ASNI/ISEA 105 and the EN388.

ANSI Standards

Cut Level 1

Light Cut Hazards:

Material handling, assembly, maintenance, packaging, warehouse, general purpose, construction

asdasd asd asd

200 - 499 grams

Cut Level 2

Light/Medium Cut Hazards:

Material handling, assembly, maintenance, packaging, warehouse, general purpose, construction, metal handling, appliance manufacturing

500 - 999 grams

Cut Level 3

Light/Medium Cut Hazards:

Material handling, assembly, maintenance, packaging, warehouse, general purpose, construction, metal handling, appliance manufacturing

1000 - 1499 grams

Cut Level 4

Medium Cut Hazards:

Bottle and light glass handling, canning, dry walling, electrical, carpet installation, HVAC, paper production, automotive assembly, metal handling, metal stamping, packaging, warehouse, appliance manufacturing

1500 - 2199 grams

Cut Level 5

Medium Cut Hazards:

Bottle and light glass handling, canning, dry walling, electrical, carpet installation, HVAC, paper production, automotive assembly, metal handling, metal stamping, packaging, warehouse, appliance manufacturing

2200 - 2999 grams

Cut Level 6

Medium/Heavy Cut Hazards:

Bottle and light glass handling, canning, dry walling, electrical, carpet installation, HVAC, paper production, automotive assembly, metal handling, metal stamping, packaging, warehouse, appliance manufacturing

3000 - 3999 grams

Cut Level 7

Medium/Heavy Cut Hazards:

Bottle and light glass handling, canning, dry walling, electrical, carpet installation, HVAC, paper production, automotive assembly, metal handling, metal stamping, packaging, warehouse, appliance manufacturing, meat processing

4000 - 4999 grams

Cut Level 8

Heavy Cut Hazards:

Bottle and light glass handling, canning, dry walling, electrical, carpet installation, HVAC, paper production, automotive assembly, metal handling, metal stamping, packaging, warehouse, appliance manufacturing, meat processing

5000 - 5999 grams

Cut Level 9

Heavy Cut Hazards:

Bottle and light glass handling, canning, dry walling, electrical, carpet installation, HVAC, paper production, automotive assembly, metal handling, metal stamping, packaging, warehouse, appliance manufacturing, meat processing

6000+ grams

EN388 Standards

A

B

C

D

E

F

Cut Level A

Light Cut Hazards:

Light material handling, small parts assembly without sharp edges

204 - 508 grams/2 - 4.9 newtons

Cut Level B

Light/Medium Cut Hazards:

Packaging, warehouse, light-duty general purpose

509 - 1,019 grams/5 - 9.9 newtons

Cut Level C

Light/Medium Cut Hazards:

Light duty metal handling, metal stamping, HVAC, light duty glass handling, plastics, material handling

1,020 - 1,529 grams/10 - 14.9 newtons

Cut Level D

Medium Cut Hazards:

Light duty metal handling, appliance manufacturing, bottle and light glass handling, canning, dry walling, electrical, carpet installation, HVAC

1,530 - 2,242 grams/15 - 21 newtons

Cut Level E

Medium Cut Hazards:

Metal stamping, sheet metal handling, glass handling, automotive assembly

2,243 - 3,058 grams/22 - 29.9 newtons

Cut Level F

Heavy Cut Hazards:

Heavy-duty metal stamping, metal recycling, food processing, pulp, and paper

3,059+ grams/30+ newtons

Shell Materials

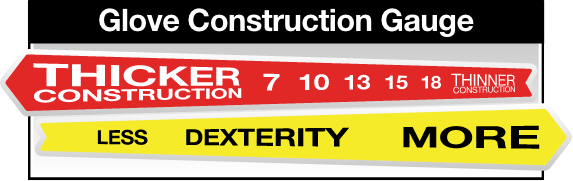

Gloves can be constructed from a number of different materials. Each material offers varying levels of protection and comfort. In addition to the material type, each shell is given a gauge.

The gauge of a shell identifies how many needles are used per linear inch on a knitting machine. The smaller the gauge, the thicker the shell. 7 gauge is the thickest shell and 18 gauge is the thinnest, lightest weight shell.

Polyester

- Monofilament Yarn

- Single Fiber, Not Twisted

Nylon

- Man-Made Yarn

- Durable

- Excellent Abrasion Resistant

- Varying Luster

HPPE

- High Performance Polyethylene

- Same as HDPE or UHMwPE

- Offers Cut Levels A2-A3

HPPE with Fiberglass and/or Stainless Steel

- Reinforced HPPE

- The addition of fiberglass can increase to A3 cut level

- The addition of stainless steel can increase to A5 or higher cut level

Kevlar®

- Engineered Yarn by DuPont®

- Fire Resistant

- Offers High Cut Levels

- Is available in gloves and cut sleeves

DYNEEMA® Diamond

- Uses embedded micro fibers to strengthen fibers up to 2x

- Offers higher cut levels

- Has great durability and abrasion resistance

- Cool to the touch

TekTye® by Radians

- Proprietary, Engineered Yarn by Radians

- High Cut Levels of A4 without the use of Glass Fiber or Stainless Steel

When Glass Fiber or Stainless Steel is used in the shell over time those fibers will break. This not only causes possible irritation to the skin in the areas of the break but also in that exact spot of the breakage the glove is no longer an A4 but rather closer to an A2.

Palm Coatings

To address specific work-related hand protection issues, Radians offers gloves in several different types of palm coatings. Palm coatings allow for better gripping capabilities and tactile sensation without losing dexterity.

Smooth Nitrile

- Excellent Abrasion Resistance

- Synthetic Rubber, Latex Free

- Excellent Puncture Resistance

- Tactile Sensitivity and Flexible Grip

Foam Nitrile

- Lightweight Micro Texture

- Good Grip in Wet or Dry Applications

- Breathable, Flexible and Porous

- Excellent Abrasion Resistance

Sandy Foam Nitrile

- Micro Roughened Texture

- Excellent Grip in Wet or Dry Applications

- Breathable, Flexible and Porous

- Excellent Abrasion Resistance

Foam Latex

- Micro Texture

- Better Breathability and Comfort

- Excellent Flexibility

- Resistant to Tears and Cuts

Sandy Foam Latex

- Micro-Roughened Texture

- Better Breathability and Comfort

- Excellent Flexibility

- Resistant to Tears and Cuts

Crinkle Latex

- Rough Texture for Better Grip and Abrasion

- Better Breathability and Comfort

- Excellent Flexibility

- Resistant to Tears and Cuts

PU (Polyurethane)

- Semi-Smooth Texture

- Extremely Flexible

- Superior Dexterity

- Not as Durable as Nitrile or Latex

FDG® By Radians

- Proprietary, Engineered Coating by Radians

- Flexible and Durable

- Provides Better Grip than Nitrile

When dealing with Foam Nitrile, to get the best grip you must give up some abrasion resistance, and to get the best abrasion resistance you have to give up some grip. With FDG you no longer must give up any of these. You get the best of both worlds.

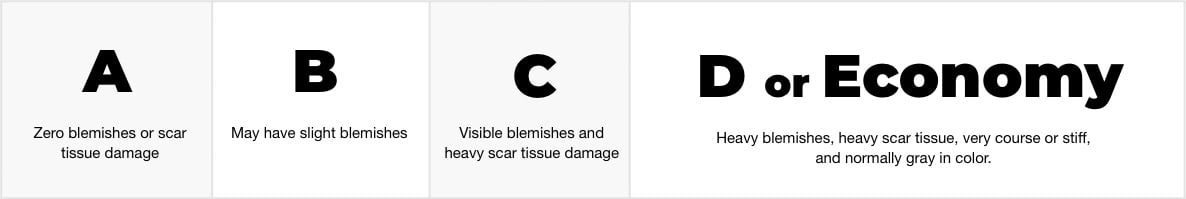

Grades of Leather

Despite mechanization, leather tanning consists of a complex series of treatments that require considerable time and energy. The purpose of the tanning process is to alter the protein structure of the skin to increase its durability, texture, and appearance. All natural hides are sorted at the tannery and are ranked by quality.

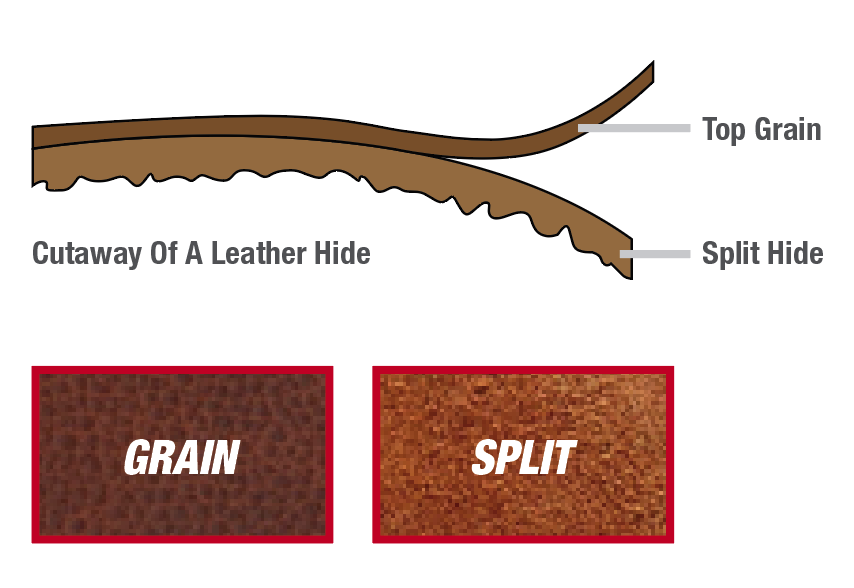

Grain vs. Split Leather

Grain leather comes from the top portion of the hide where the hair follicles have been removed. It is smooth to the touch.

Split leather is created by “splitting” the grain leather away from the underside of the hide. Turning one hide into two hides allows for more gloves per square meter to be produced. Split leather is rough to the touch.

If you want longevity, then specify grain leather gloves. If you are trying to outfit or protect temporary workers for intermittent jobs, then split leather gloves offer you cost savings and the necessary hand protection.

Types of Leather

Cowhide

- Most common leather used for gloves

- Moderately priced

- Durable with good abrasion resistance

- Warmer than pigskin or goatskin

- Stiffens when it gets wet

- More heat resistant

Pigskin

- Offers greatest breathability

- Becomes softer with use

- Withstands moisture without getting stiff

- Dries soft and stays flexible

- Doesn't loose it shape or function when laundered

Goatskin

- Strongest and most durable

- Excellent abrasion resistance

- Great for tasks that require dexterity

- One of the softest leathers available

Want more information?

All of the information from this page, and more, can be found in our print-ready Cut-Glove and Leather Glove Fast Fact guides.

You can also Contact Us to learn about our Hand Protection Assessment program.

We can help review your job sites' hazards and advise on the protection needed.